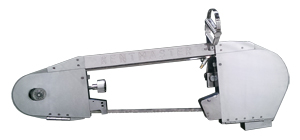

PIG & LAMB HOCK CUTTER

Model: M-1

Part No: 6600000

When it comes to sheep & goat processing, the efficiency of your machinery can be key to a smooth and successful operation.

We manufacture and supply everything required, from heavy-duty machinery for abattoirs to the finest blades for professional chefs. You’ll find us at every major Expo around the world. Innovation in the food processing industry is moving at a rapid pace, for you to keep up click below and we'll make sure you know what you need, how it works and ensure your workflow runs smoothly. "OPEN THE GUIDE BELOW TO SEE THE FLOOR PLAN AND EQUIPMENT"

Model: M-1

Part No: 6600000

Model: C-BLADE

Part No: 40000120-670

Model: MATADOR® SUPER SECURIT 3000

Part No: 990104

Model: Sheep pelt puncher

Part No: 998300

Model: Pneumatic Electric Pizzle Sealer

Part No: 996301

Model: HG1

Part No: 6702000 (.22) 6703000 (.25) 6702100 (.22) MUSHROOM HEAD 6703100 (.25) MUSHROOM HEAD

Model: Quick Set

Part No: 6310000

Model: SBS-II

Part No: 6240500

Model: SBS-II

Part No: 6240500

Model: M-5

Part No: 6606000

Model: K-9

Part No: 1910000

Model: VFR 2000

Part No: 997720

Model: VAC-SAN

Part No: 997510D

Model: TG-32

Part No: 1130000 (TG-32)

Model: BM-V-SD

Part No: 1708100 (electric or air triggers)

Model: TURBO-III

Part No: 6303000

Do you operate a slaughterhouse, abattoir, meat processing facility, or butchery.

If so, then you need the right machinery for your business to be successful.

As you know sheep and goat culling is an essential part of the slaughterhouse process and can add substantially to your bottom line.

It doesn’t have to be difficult though! With the latest advancements in abattoir machinery, sheep and goat culling has never been easier to prepare animals quickly while maintaining solid processing workflow and food safety standards.

When it comes to choosing abattoir machinery for sheep and goats, there are several factors to consider.

Firstly, the size and capacity of the machinery should be suitable for the number of animals that need to be processed. Additionally, the efficiency and speed of the machinery can greatly impact the overall operations of the abattoir.

It is also important to consider the safety features of the machinery to ensure the well-being of both the animals and the operators.

Furthermore, the cost and maintenance requirements of the machinery should be taken into account to ensure a sustainable and profitable business.

This is where Kentmaster New Zealand comes in, since the 1990s we have helped set up and supply all the machinery to abattoirs, slaughterhouses, and processing facilities all throughout the chain.

With our consultation and advice abattoir owners are assured of making correct informed decisions when selecting the right machinery for their operations.

Here at Kentmaster New Zealand, we stock only premium Sheep and goat culling and cutting equipment for the New Zealand market. Take a look at our stock, it’s easy to order. Alternatively, give us a call for any further advice.