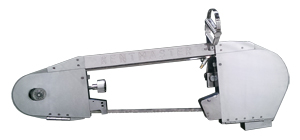

PIG & LAMB HOCK CUTTER

Model: M-1

Part No: 6600000

We have been providing superior industrial pig culling equipment for over 75 years.

We manufacture and supply everything required, from heavy-duty machinery for Freezing Works to the finest blades for professional chefs. You’ll find us at every major Expo around the world.

Innovation in the food processing industry is moving at a rapid pace, for you to keep up click below and we'll make sure you know what you need, how it works and ensure your workflow runs smoothly.

OPEN THE GUIDE BELOW TO SEE THE FLOOR PLAN AND EQUIPMENT

Model: M-1

Part No: 6600000

Model: C-BLADE

Part No: 40000120-670

Model: MATADOR® SUPER SECURIT 3000

Part No: 990104

Model: HG1

Part No: 6702000 (.22) 6703000 (.25) 6702100 (.22) MUSHROOM HEAD 6703100 (.25) MUSHROOM HEAD

Model: Quick Set

Part No: 6310000

Model: KCS-1

Part No: 2021000

Model: BST-I

Part No: 1151000

Model: KM-160

Part No: 1600400

Model: AHB

Part No: 6002300

Model: EHB

Part No: 1000600

Model: HC-IV

Part No: 6540000

Model: B-GUN

Part No: 6800000

Model: M-5

Part No: 6606000

Model: K-9

Part No: 1910000

Model: ZIP SAW

Part No: 1900000

Model: HKM-III

Part No: 6623000

Model: COLT

Part No: 1001600

Model: SL-1100

Part No: 6320000

Model: HSC-650

Part No: 6220100

Model: SC-650

Part No: 6220000

Model: SC-550

Part No: 6210000

Model: TG-32

Part No: 1130000 (TG-32)

Model: BM-V-SD

Part No: 1708100 (electric or air triggers)

Model: TURBO-III

Part No: 6303000

Model: AHC-I

Part No: 6230000

Are you looking for a streamlined way to deliver high-quality pork products with maximum efficiency and minimal waste?

In the abattoir, this is achievable through the use of specialised machinery.

From culling pigs prior to slaughter, to processing carcasses into cuts of meat, efficient workflow processes can be established in any facility.

Kentmaster New Zealand has a proven track record since the 1990s of supplying the New Zealand meat industry with equipment that aids automation within the production process.

By understanding which tools are best suited for each part of your business’s operations, you can benefit from greater operational efficacy and improved productivity at every stage.

The pork production process is a complex system that requires a variety of key components to work together seamlessly.

One such component is the abattoir machinery, which plays a vital role in the process of preparing and packaging pork products for distribution.

The machines we stock are designed to efficiently and effectively carry out a range of tasks, from stunning and bleeding the animals to removing their hair and skin and preparing them for processing into a wide range of pork products.

With the right machinery, pork producers can increase their efficiency and output, cutting processing times and reducing costs while still producing high-quality, safe, and tasty pork products for consumers around New Zealand and beyond.

Here at Kentmaster New Zealand, you will find a range of products on our site that cover pork culling and processing. So take a look and see if we have what you are looking for or give us a call for more advice.